PRODUCTS

YG-S

SUNSHINE

YG1000-S

Siemens/Schneider/Mitsubishi/AirTac/Delta/Can be customized

50-5000ml

1000-4500 Bottles/Hour

Liquid detergent,Hand sanitizer,Shampoo,Chemicals liquid.

One Year and Life-Long Technical Support

SUS 304/316

Engineers Available to Service Overseas

| Availability: | |

|---|---|

The Lotion Filling Machine is an advanced automatic filling system designed for cosmetic lotions, body lotions, moisturizing lotions, skincare emulsions, and light creams. Engineered for precision, hygiene, and efficiency, it ensures smooth handling of medium- to high-viscosity products while maintaining consistent fill volumes and premium packaging quality.

This machine is widely used in the cosmetics, personal care, pharmaceutical, and daily chemical industries, helping manufacturers scale production while meeting strict quality and hygiene standards.

AUTOMATIC LOTION FILLING MACHINE INTRODUCTION

A Lotion Filling Machine is specialized equipment used to accurately dispense lotion products into bottles, jars, or containers. It typically uses a servo-driven piston filling system, making it ideal for products with higher viscosity or creamy textures.

Suitable for filling:

Body lotion

Hand and face lotion

Moisturizing and whitening lotion

Skincare emulsions

Light creams and gels

Servo-controlled piston filling technology

Filling accuracy up to ±0.2-0.3%

Stable output for thick and creamy products

Product-contact parts made of SUS304 / SUS316L stainless steel

Smooth surfaces with no dead corners for easy cleaning

Fully compliant with cosmetic and pharmaceutical hygiene requirements

Automatic bottle positioning, filling, and discharge

PLC + touchscreen control system for easy operation

Recipe memory for different lotion types and bottle sizes

Suitable for bottles and jars made of PET, HDPE, glass, and plastic

Filling range: 10ml – 5000ml (customizable)

Quick and tool-free size changeover

Anti-drip filling nozzles prevent leakage and mess

Optional bottom-up filling to reduce air bubbles

Consistent filling appearance for premium cosmetic products

| Item | Specification |

|---|---|

| Filling Volume | 50 ml – 5000 ml (customizable) |

| Filling Heads | 4 / 6 / 8 / 12 / 16 / 20 (optional based on capacity needs) |

| Production Capacity | 1,000 – 4,500 bottles/hour (depending on bottle size and number of heads) |

| Filling Accuracy | ≤ ±0.1% |

| Bottle Types | Round, flat, or square bottles of various materials |

| Machine Dimensions | 1800×1300×2250 mm (4–6 heads) 2800×1500×2250 mm (20 heads) |

| Power Supply | 220V / 380V / 415V, 50/60 Hz (customizable) |

| Air Supply | 0.6 – 0.8 MPa clean compressed air |

| Material Construction | SUS304 or SUS316 stainless steel, resistant to chemical corrosion |

| Control System | Siemens / Schneider / Mitsubishi / Delta components (optional) |

| Warranty | 1-year warranty with lifetime technical support |

1.The filling nozzels diameter of the edible oil filling machine can be customized accoridng to the size of the bottle mouth.

2.The filling nozzle is installed on the ground floor to prevent the bottle from being contaminated during filling.

3.The filling nozzle can be lifted and lowered by a servo motor to reduce the amount of foaming during filling. It is suitable for filling liquids that are prone to foaming.

1.All the pistons are made of SUS304/316 food grade material.The piston ring is also made of food grade material. Wear and corrosion resistant

2.The inner wall of the piston cylinder is smooth, ensuring no residue after filling and high filling accuracy.

3.With cylinder removal function, the piston ring can be lowered out of the piston cylinder for easy cleaning.

1.Adopt high-power Panasonic brand servo motor, stable operation and high precision.

2.It adopts double-screw structure and chain drive, which can transmit sufficient power to drive the piston ring, with stable structure and high operation precision.

3.Equipped with high and low position protection to prevent the piston ring from falling out of the piston cylinder, without causing leakage, high safety.

1.The internal pipelines of the filling machine can be perfectly cleaned with CIP cleaning fluid, from the material box to the piston cylinder to the filling nozzle, with no dead angles.

2.The material box can be equipped with heating, stirring, high and low level gauges and other functions, suitable for a variety of different liquids filling.

FDA Certified Food Grade Filling Pipe

Our Edible Oil Filling Machine can used FDA certified food grade filling pipe.

All filling tubes are quick-connect, easy to disassemble and clean.No residue when filling various edible oils, sauces and other liquids.

Servo Motor Diving Nozzle

Servo motor can be used to raise and lower the brake fluid filling machine nozzles, which can rise while filling, so that the liquid is always under the filling nozzle to reduce the generation of bubbles.

CIP Material Tank

The top of the brake fluid filling machine can be replaced with a CIP storage tank, which can be equipped with heating, stirring, high and low liquid level display, CIP interface and other functions

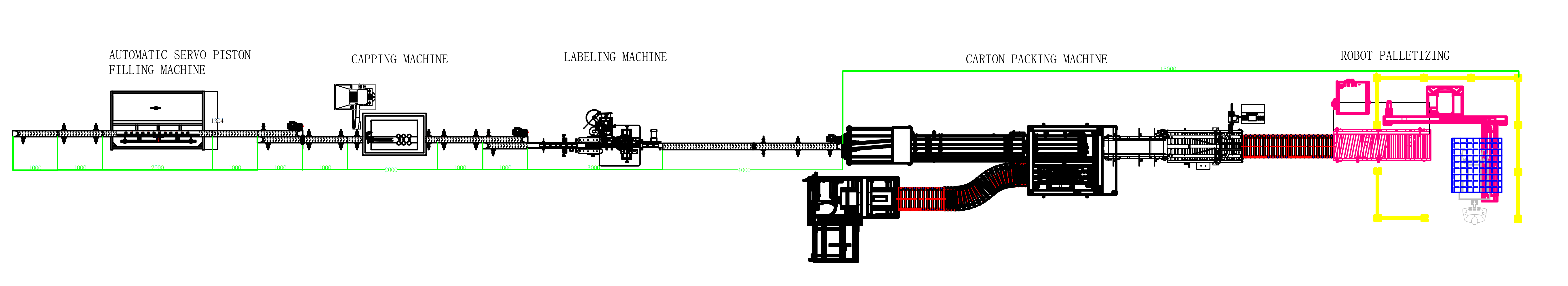

Here are some machines we can working together with brake fluid filling machine.All the equipment can be connected and used together to complete the entire line production of various bottle types.

Automatic Palletizer Machine

The Lotion Filling Machine can be integrated into a complete automatic production line, including:

Bottle or jar unscrambler

Lotion Filling Machine

Automatic capping machine

Induction sealing machine

Labeling machine

Date coding or batch printing system

A turnkey solution helps manufacturers improve efficiency, reduce labor costs, and ensure consistent product quality.

As a high-quality hand sanitizer filling machine manufacturer from China, we can provide customers with one-stop service. We can provide customers with filling machines, capping machines, labeling machines, liquid nitrogen filling machines, and carton unpacking machines. Packing machines, film wrapping machines, palletizers and other equipment. For different bottle types and caps, we have a variety of equipment to choose from, suitable for different products, and connect them into an efficient hand sanitizer production line to achieve safe and stable fully automated production.

| Bottle Unscrambler Machine | The bottle unscrambler is for fully automatic arrange the bottles according to the direction and send it to the conveyor line.Wide range of applications, can be customized for different sizes and shapes of bottles. |

Hand Sanitizer filling Machine | Servo piston filling machine, weighing filling machine, magnetic pump filling machine, rotor pump filling machine, all kinds of filling machines can meet 100-5000ml, 5L or more of different capacity filling. |

| Capping Machine | According to the design of different bottles, capping machine and capping machine will complete the capping and capping sealing work of various bottles. |

| Labeling Machine | Suitable for all kinds of round bottles, flat bottles, square bottles, shaped bottles single-sided, double-sided, multi-sided labeling work. |

| Carton Packing Mahcine | Arrange the filled oil bottles in order, neatly put them in the open carton, and finally seal the box to complete the packaging work. |

| Robot Palletizing Machine | Through the palletizing robot, the packaged cartons are automatically palletized, improving work efficiency and freeing workers from tired physical work |

| Conveyor System | We provide custom conveyor systems designed to seamlessly transport containers to and from the filling machine. These systems are engineered for reliability and optimize the flow of your production. |

Liquid Disinfectant Filling Machine

Capping Machine

Labeling Machine

Bottle Unscrambler Machine

Carton Packing Machine

Robot Palletizing Machine