PRODUCTS

Liquid Soap Filling Machine

SUNSHINE

YG1000-S

Siemens/Schneider/Mitsubishi/AirTac/Delta/Can be customized

50-5000ml

1000-4500 Bottles/Hour

Liquid detergent,Hand sanitizer,Shampoo,Chemicals liquid.

One Year and Life-Long Technical Support

SUS 304/316

Engineers Available to Service Overseas

| Availability: | |

|---|---|

The Hand Sanitizer Servo Piston Filling Machine is a high-precision, fully automatic liquid filling system designed specifically for filling viscous and semi-viscous products such as hand sanitizers, gels, disinfectants, and liquid soaps. This machine integrates advanced servo control technology, piston metering, and a hygienic stainless-steel structure, making it an ideal solution for modern liquid packaging lines in cosmetic, pharmaceutical, chemical, and personal care industries.

Each piston is controlled by a high-precision servo motor, allowing individual adjustment and synchronization of all filling heads. This ensures accurate volume control (±0.2%) and flexible filling speed settings.

The machine can handle a wide range of liquid viscosities—from thin alcohol-based sanitizers to thick gel-type sanitizers—without changing major components. It’s compatible with various bottle shapes and sizes, including round, square, and flat bottles made of plastic or glass.

Equipped with a PLC control system and a color touchscreen, the operator can easily set parameters such as filling volume, speed, delay time, and production counting. The system stores multiple recipes for different product types, allowing quick changeovers.

The piston and cylinder system is designed with quick-release connectors for easy disassembly and cleaning. The contact parts are made of 316L stainless steel, ensuring hygiene, corrosion resistance, and compliance with GMP standards.

The filling nozzles feature a drip-proof structure and can be optionally equipped with diving-type filling heads that enter the bottle before dispensing liquid. This minimizes foaming and avoids spillage for high-viscosity or foamy products.

The servo system allows flexible control over filling speed and acceleration, which can be adjusted according to the viscosity of the product. The filling volume can be changed electronically without manual mechanical adjustment.

The machine can be configured with 2, 4, 6, 8, 10, 12,16,20 or more filling heads depending on production capacity requirements. It can also be integrated with automatic capping machines, labeling machines, and conveyors to form a complete packaging line.

The piston mechanism offers precise control over the liquid amount being filled, ensuring each bottle receives exactly the same volume. This reduces product wastage and prevents overfilling or underfilling.

Unlike other filling machines, piston fillers can handle high-viscosity liquids such as shampoos, conditioners, lotions, and other thick liquids. The piston mechanism can easily draw and fill viscous products without clogging or dripping.

The machine is capable of high-speed filling, making it suitable for large-scale production. The automated filling process significantly increases throughput and reduces labor costs.

The filling volume can be easily adjusted according to the requirements of different bottle sizes or product formulations. This flexibility makes the machine ideal for diverse product ranges.

Most piston filling machines are fully automated, with integrated control panels for easy operation. This reduces the need for manual labor and minimizes human error, allowing for a smoother production process.

Piston filling machines are made of durable materials like stainless steel, which makes them resistant to corrosion and wear. The design is simple, reducing the likelihood of malfunction and making maintenance easy and cost-effective.

The precise control mechanism ensures minimal spillage or leakage during the filling process. It is particularly beneficial for expensive or high-value liquids, ensuring minimal waste.

The design of the machine ensures that it is easy to clean and maintain, which is crucial for industries such as cosmetics and food. Parts that come into contact with the product are designed for quick and thorough cleaning, ensuring compliance with hygiene standards.

| Item | Specification |

|---|---|

| Filling Volume | 50 ml – 5000 ml (customizable) |

| Filling Heads | 4 / 6 / 8 / 12 / 16 / 20 (optional based on capacity needs) |

| Production Capacity | 1,000 – 4,500 bottles/hour (depending on bottle size and number of heads) |

| Filling Accuracy | ≤ ±0.1% |

| Bottle Types | Round, flat, or square bottles of various materials |

| Machine Dimensions | 1800×1300×2250 mm (4–6 heads) 2800×1500×2250 mm (20 heads) |

| Power Supply | 220V / 380V / 415V, 50/60 Hz (customizable) |

| Air Supply | 0.6 – 0.8 MPa clean compressed air |

| Material Construction | SUS304 or SUS316 stainless steel, resistant to chemical corrosion |

| Control System | Siemens / Schneider / Mitsubishi / Delta components (optional) |

| Warranty | 1-year warranty with lifetime technical support |

1.The filling nozzels diameter of the edible oil filling machine can be customized accoridng to the size of the bottle mouth.

2.The filling nozzle is installed on the ground floor to prevent the bottle from being contaminated during filling.

3.The filling nozzle can be lifted and lowered by a servo motor to reduce the amount of foaming during filling. It is suitable for filling liquids that are prone to foaming.

1.All the pistons are made of SUS304/316 food grade material.The piston ring is also made of food grade material. Wear and corrosion resistant

2.The inner wall of the piston cylinder is smooth, ensuring no residue after filling and high filling accuracy.

3.With cylinder removal function, the piston ring can be lowered out of the piston cylinder for easy cleaning.

1.Adopt high-power Panasonic brand servo motor, stable operation and high precision.

2.It adopts double-screw structure and chain drive, which can transmit sufficient power to drive the piston ring, with stable structure and high operation precision.

3.Equipped with high and low position protection to prevent the piston ring from falling out of the piston cylinder, without causing leakage, high safety.

1.The internal pipelines of the filling machine can be perfectly cleaned with CIP cleaning fluid, from the material box to the piston cylinder to the filling nozzle, with no dead angles.

2.The material box can be equipped with heating, stirring, high and low level gauges and other functions, suitable for a variety of different liquids filling.

FDA Certified Food Grade Filling Pipe

Our Edible Oil Filling Machine can used FDA certified food grade filling pipe.

All filling tubes are quick-connect, easy to disassemble and clean.No residue when filling various edible oils, sauces and other liquids.

Servo Motor Diving Nozzle

Servo motor can be used to raise and lower the brake fluid filling machine nozzles, which can rise while filling, so that the liquid is always under the filling nozzle to reduce the generation of bubbles.

CIP Material Tank

The top of the brake fluid filling machine can be replaced with a CIP storage tank, which can be equipped with heating, stirring, high and low liquid level display, CIP interface and other functions

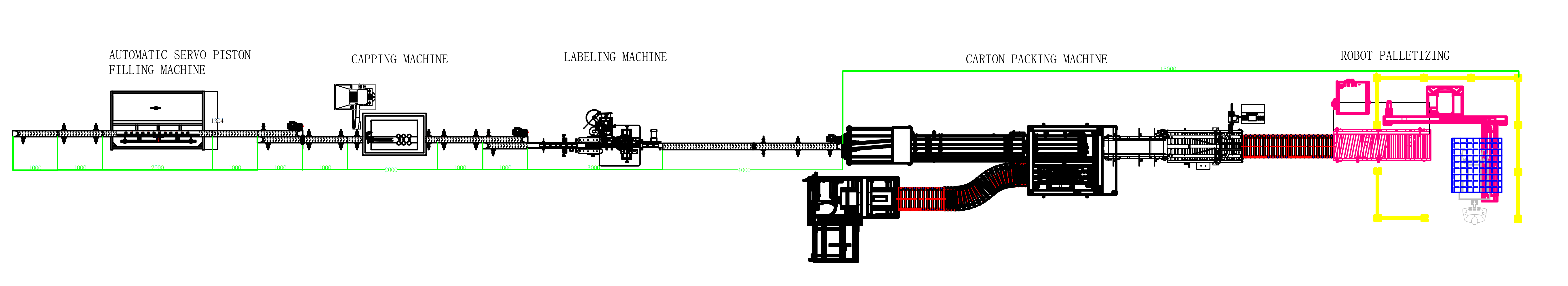

Here are some machines we can working together with brake fluid filling machine.All the equipment can be connected and used together to complete the entire line production of various bottle types.

Automatic Palletizer Machine

As a high-quality hand sanitizer filling machine manufacturer from China, we can provide customers with one-stop service. We can provide customers with filling machines, capping machines, labeling machines, liquid nitrogen filling machines, and carton unpacking machines. Packing machines, film wrapping machines, palletizers and other equipment. For different bottle types and caps, we have a variety of equipment to choose from, suitable for different products, and connect them into an efficient hand sanitizer production line to achieve safe and stable fully automated production.

| Bottle Unscrambler Machine | The bottle unscrambler is for fully automatic arrange the bottles according to the direction and send it to the conveyor line.Wide range of applications, can be customized for different sizes and shapes of bottles. |

Hand Sanitizer filling Machine | Servo piston filling machine, weighing filling machine, magnetic pump filling machine, rotor pump filling machine, all kinds of filling machines can meet 100-5000ml, 5L or more of different capacity filling. |

| Capping Machine | According to the design of different bottles, capping machine and capping machine will complete the capping and capping sealing work of various bottles. |

| Labeling Machine | Suitable for all kinds of round bottles, flat bottles, square bottles, shaped bottles single-sided, double-sided, multi-sided labeling work. |

| Carton Packing Mahcine | Arrange the filled oil bottles in order, neatly put them in the open carton, and finally seal the box to complete the packaging work. |

| Robot Palletizing Machine | Through the palletizing robot, the packaged cartons are automatically palletized, improving work efficiency and freeing workers from tired physical work |

| Conveyor System | We provide custom conveyor systems designed to seamlessly transport containers to and from the filling machine. These systems are engineered for reliability and optimize the flow of your production. |

Liquid Soap Filling Machine

Capping Machine

Labeling Machine

Bottle Unscrambler Machine

Carton Packing Machine

Robot Palletizing Machine