PRODUCTS

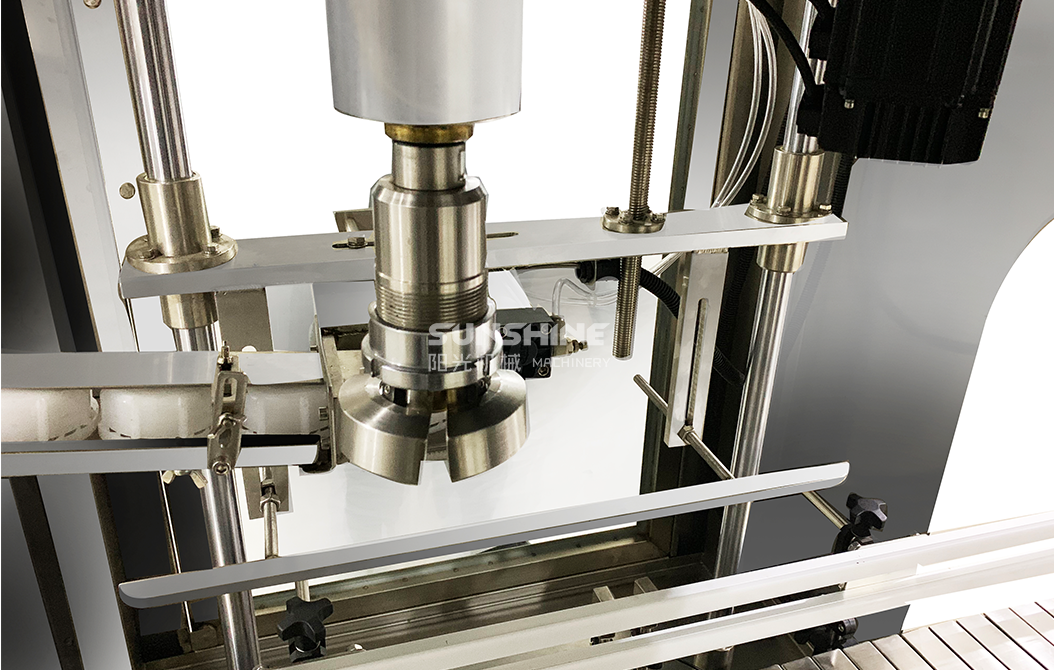

Servo Capping Machine

SUNSHINE

FD-01

Siemens/Schneider/Mitsubishi/AirTac/Delta/Can be customized

220/380/415V;50/60HZ

1000-1200 Bottles/Hour

Oil,Sauce,Chemicals bottle capping

One Year and Life-Long Technical Support

SUS 304/316

Engineers Available to Service Overseas

| Availability: | |

|---|---|

Single-Head Servo Capping Machine is an advanced piece of packaging equipment designed for automatic tightening or sealing of bottle caps with high accuracy and consistency. It is widely used in industries such as pharmaceuticals, cosmetics, food & beverage, chemicals, and daily care products. The servo-driven mechanism provides precise torque control, ensuring reliable sealing without damaging the caps or bottles.

1.Bottle Feeding: Bottles are conveyed to the capping station through an automatic conveyor system.

2.Cap Placement: Depending on configuration, caps can be fed automatically by a cap feeder or manually placed.

3.Servo-Controlled Capping:The servo motor drives the capping head, applying precise torque to tighten the cap.Torque and speed can be set and adjusted via the control panel to suit different bottle and cap types.

4.Bottle Discharge: Once capped, the bottles are transferred to the next station (labeling, inspection, or packing).

Capping machines can be customised according to different production requirements of customers.

1.In order to accommodate a wide range of different types of caps, our capping machines can be equipped with a variety of different cap feeders,Rotary cap sorting machines, Vibratory plate cap sorting machines.

2.If there is a requirement for explosion-proof category, we can use explosion-proof grade electrical components for our motors, photoelectrics, electrical components, etc. We have installed explosion-proof electrical cabinets and explosion-proof buttons to ensure safety.

Edible oil

Lubricating oil

Food & Sacue

Personal Care & Daily Chemical

Pesticide & Agro Chemical

| Parameter Technica | |

| Producton Speed | 1000-1200 Bottles/hour |

| Machine Diemension | 2000x1300x2250mm |

| Weight | 800KG |

| Power Supply | 220/380/415V ; 50/60HZ |

| Suitable Bottles | Round Bottles,Falt Bottles,Square Bottles(Can be customized) |

| Suitable Bottles Size | Bottle Diameter:φ40mm-φ100mm Cap Diameter:φ10mm-φ50mm |

| Air Supply | 0.6-0.8Mpa Clean Air |

1.he capping head (clamping chuck) can be replaced in just a few minutes without tools.

2.Enables fast changeovers for different cap sizes and bottle types, greatly improving production efficiency.

3.High-precision torque adjustment ensures consistent capping quality.

4.Prevents over-tightening, slippage, or damage to caps and bottles.

1.Integrated cap feeder automatically delivers and replenishes caps to the capping head.

2.Suitable for screw caps, press-on caps, CRC (child-resistant caps), pump caps, and flip-top caps.

3.Compatible with round, square, or irregular bottles.

Here are some machines we can working together with single head servo capping machine.All the equipment can be connected and used together to complete the entire line production of various pail/drum types.

Bottle Unscrambler

Serco Piston Filling Machine

Tracking Capping Machine

Corrosion Liquid Filling Machine

Gravity Filling Machine

Bottle Labeling Machine

Carton Packing Machine

Automatic Palletizer Machine