Views: 0 Author: Site Editor Publish Time: 2026-01-03 Origin: Site

Choosing between an automatic and a semi-automatic liquid filling machine is one of the most important decisions when planning or upgrading a filling line. The right choice directly affects production efficiency, labor cost, filling accuracy, scalability, and return on investment (ROI).

This guide breaks down the differences clearly and helps you decide which option fits your business best.

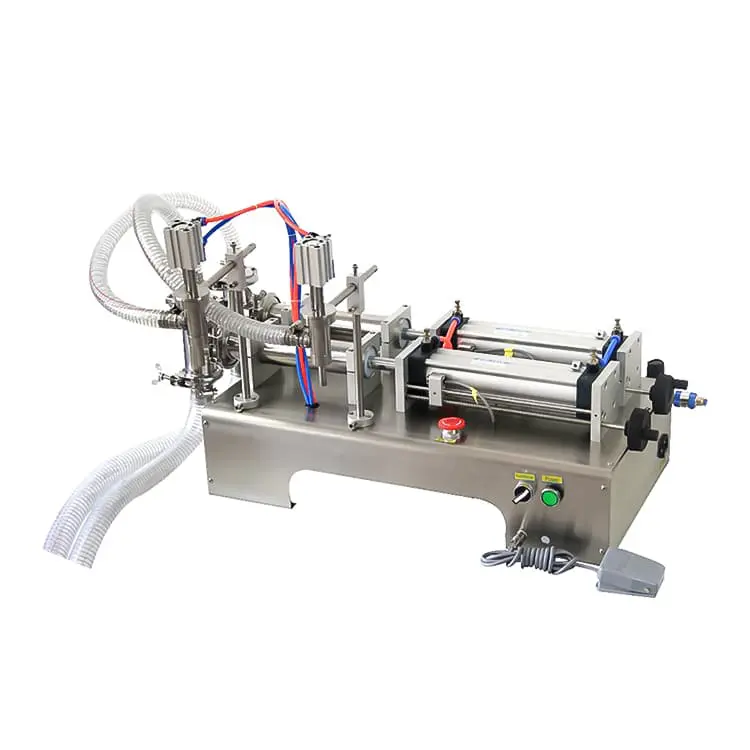

A semi-automatic liquid filling machine requires manual involvement for part of the operation—usually bottle placement, start/stop control, or container removal—while the machine handles the filling process itself.

Manual bottle loading and unloading

Operator starts each filling cycle

Lower initial investment

Simple structure and easy maintenance

Small and medium-sized factories

Startups and pilot production lines

Low to medium production volumes

Frequent product changes or short runs

An automatic liquid filling machine performs the entire filling process without manual intervention, often integrating with capping, labeling, and packaging systems to form a complete production line.

Automatic bottle feeding, filling, and discharge

High-speed and consistent output

PLC & HMI control for precision and automation

Designed for continuous production

Medium to large-scale manufacturers

High-volume production lines

Factories focused on efficiency and labor reduction

Standardized product formats

| Feature | Semi-Automatic Filling Machine | Automatic Filling Machine |

|---|---|---|

| Automation Level | Partial | Full |

| Production Speed | Low to Medium | Medium to High |

| Labor Requirement | High | Low |

| Initial Cost | Lower | Higher |

| Filling Accuracy | Good | Excellent |

| Scalability | Limited | High |

| Best For | Small batches, startups | Mass production |

If your production volume is limited and labor cost is manageable, a semi-automatic solution provides flexibility with minimal upfront investment.

Although automatic machines cost more initially, they often deliver faster ROI through:

Reduced labor expenses

Higher output per hour

Lower product waste

Consistent filling accuracy

For long-term growth, automation is usually the more economical option.

Ask yourself the following questions:

Under a few thousand units/day → Semi-automatic

Tens of thousands/day → Automatic

Low to high viscosity liquids (water, oil, detergent, shampoo, chemicals) can be handled by both, but automatic systems offer better stability at scale.

For regulated or branded products, automatic machines provide better control and repeatability.

If expansion is expected, investing in automation early avoids costly upgrades later.

Cosmetics & Personal Care: Automatic machines ensure uniform filling and brand consistency

Food & Beverage: Automation improves hygiene and throughput

Chemical & Detergent: Automatic filling reduces operator exposure and increases safety

Small OEM Producers: Semi-automatic machines offer flexibility and low entry cost

There is no one-size-fits-all answer.

Choose a semi-automatic liquid filling machine if you prioritize flexibility, low investment, and small-batch production.

Choose an automatic liquid filling machine if your goal is high efficiency, scalability, and long-term cost savings.

The best solution is the one that matches your current needs while supporting your future growth.

If you’re unsure which liquid filling machine fits your production line, our team can help you evaluate your product, capacity requirements, and budget to design a customized filling solution.

Contact us today for a professional consultation or quotation.