Views: 0 Author: Site Editor Publish Time: 2025-08-01 Origin: Site

In modern liquid and paste packaging, servo piston filling machines have become a top choice for manufacturers seeking high precision, speed, and flexibility. One of the key components that enables this performance is the servo motor. By integrating servo motor technology into the piston filling system, these machines achieve exceptional filling accuracy and production efficiency across a wide range of industries, from food and beverage to cosmetics and chemicals.

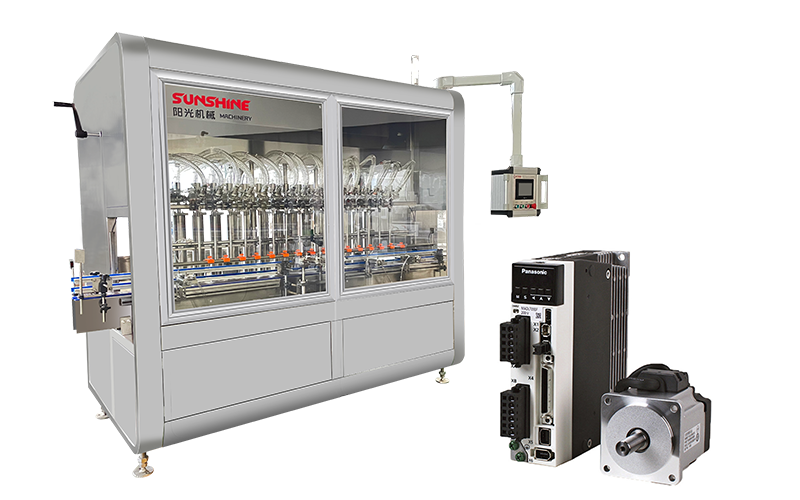

A servo piston filling machine uses a piston-and-cylinder mechanism to measure and dispense product volumes. The servo motor replaces traditional pneumatic or mechanical drives, controlling the piston's forward and backward movement with precise speed and position control. This ensures consistent fill volumes even for high-viscosity liquids, semi-liquids, and products containing small particulates.

Servo motors use closed-loop feedback systems to monitor position, speed, and torque in real-time. In a filling machine, this allows the piston to move exactly to the programmed position, ensuring that each container receives the exact desired volume.

With servo-driven technology, operators can easily adjust the stroke length, filling speed, and acceleration/deceleration curves via the touch screen. This flexibility is ideal for switching between different product types and container sizes without mechanical changes.

Servo motors allow gradual acceleration and deceleration, preventing splashing or air bubble formation when filling thick sauces, creams, oils, or gels. This is especially valuable for hot-fill or particulate-filled products.

High Filling Accuracy – Achieves ±0.5% or better volume precision.

Energy Efficiency – Consumes less energy compared to compressed air systems.

Flexibility – Quick recipe changeovers for different products and volumes.

Low Maintenance – Fewer moving parts and no need for constant pneumatic adjustments.

Improved Production Speed – Faster cycle times while maintaining accuracy.

Servo piston filling machines powered by servo motors are widely used for:

Food & Beverage: Sauces, ketchup, honey, edible oils, fruit puree.

Cosmetics: Lotions, shampoos, conditioners, creams.

Pharmaceuticals: Syrups, suspensions, nutraceutical products.

Chemicals: Lubricants, detergents, industrial fluids.

The integration of servo motor technology in piston filling machines marks a major advancement in packaging automation. By offering precise control, energy efficiency, and unmatched flexibility, servo-driven piston fillers help manufacturers meet the demands of high-quality, consistent, and cost-effective production.

If you are looking to upgrade your packaging line, investing in a servo piston filling machine is a smart choice for improving both accuracy and productivity.

1. Bosch Packaging Technolgoy |  |

Bosch Packaging Technology is a giant in the packaging industry, offering high-quality piston type filling filling machine that cater to various industries, including food, pharmaceuticals, and chemicals. Their machines are known for their precision, durability, and advanced technology. | |

2.GEA Group |  |

GEA Group is a global leader in process technology and automation. Their piston filling machine are designed with state-of-the-art technology to ensure maximum accuracy and reliability, making them a popular choice for large-scale operations. | |

3.Krones AG |  |

Krones AG offers a wide range of filling and packaging machinery, including specialized oil filling machines. Known for their innovation, Krones provides customized solutions tailored to the specific needs of their clients. | |

4.Coesia Croup |  |

Coesia Group specializes in packaging automation, and their piston filling machines are renowned for their efficiency and cutting-edge technology. Coesia’s equipment serves industries like cosmetics, pharmaceuticals, and food processing. | |

5.JBT Corporation |  |

JBT Corporation offers high-performance filling machines suitable for a variety of liquid products, including oils. Their machines boast advanced features such as quick changeover and precise filling mechanisms. | |

6.Serac Group |  |

Serac Group provides innovative filling and capping machines for liquid products, including oils. They offer customized solutions for both large-scale industries and small businesses, making them highly versatile. | |

7.CFT Group |  |

CFT Group delivers reliable, high-precision filling machines that can handle different types of oil. Their machines are particularly well-known for their energy efficiency and high-speed performance. | |

8.Accutek Packaging |  |

Accutek is a trusted name in packaging, offering a wide range of filling machines for oils. Their machines are highly customizable and suitable for businesses of all sizes, from small startups to large corporations. | |

9.SUNSHINE Packing |  |

SUNSHINE Packing Machinery CO.,LTD is a leading manufacturer of piston filling machines that cater to various industries, including food and beverages. Their piston filling machines are known for their affordability and high-quality build. | |

10.Hema Filling Systems |  |

Hema Sunshine Pacling Machinery Cs offers advanced filling machines that are both versatile and reliable. They are a great option for companies looking for efficient and durable equipment to handle a variety of oils. | |