Views: 0 Author: Site Editor Publish Time: 2025-08-10 Origin: Site

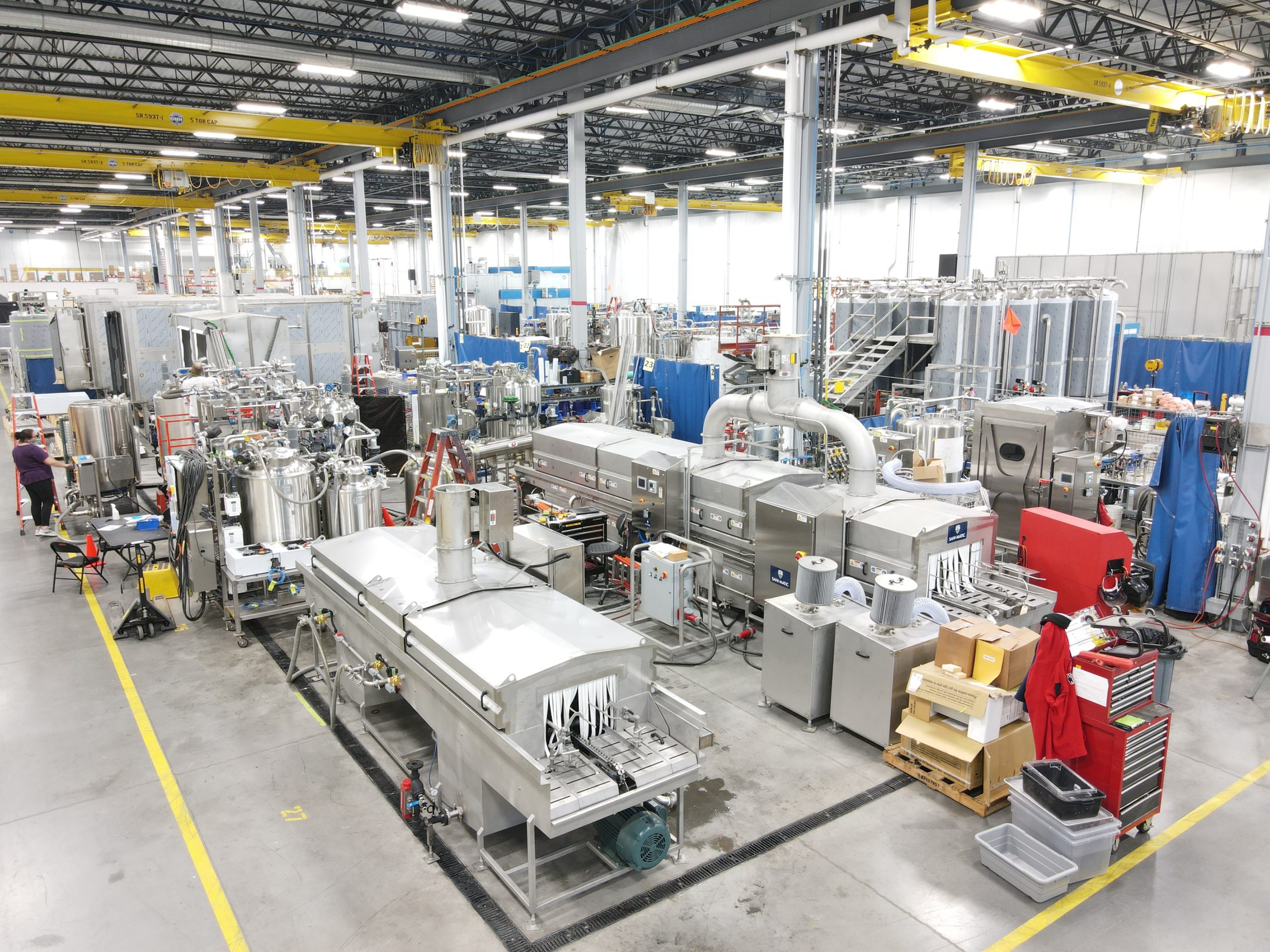

In modern manufacturing—especially in industries such as food, beverage, pharmaceuticals, and cosmetics—hygiene and efficiency are not optional; they are critical. One of the most effective solutions for ensuring both is the use of CIP (Clean-in-Place) liquid filling machines.

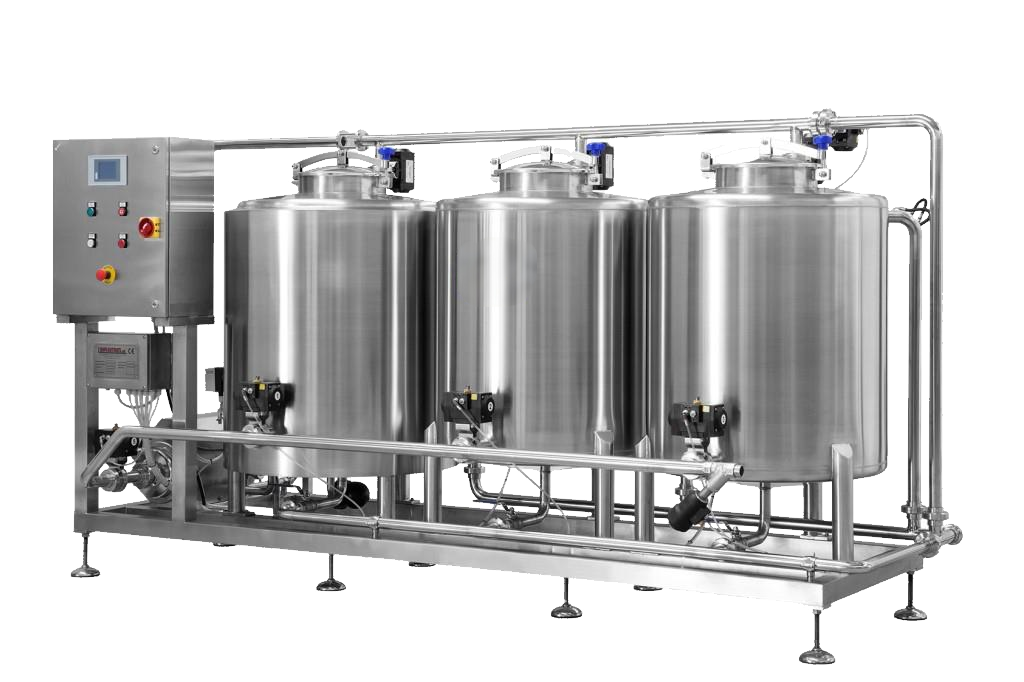

CIP systems are designed to clean the internal surfaces of pipes, tanks, and filling equipment automatically, without the need to dismantle machinery. Below, we’ll explore the key benefits of CIP liquid filling machines and why they are becoming a preferred choice for forward-thinking manufacturers.

CIP technology ensures that all product contact surfaces are thoroughly cleaned and sanitized without manual intervention.

No disassembly required – Reduces the risk of contamination caused by improper reassembly.

Consistent cleaning cycles – Ensures every production run meets strict hygiene standards.

Compliance with regulations – Helps meet GMP (Good Manufacturing Practices) and industry safety standards.

This is particularly important in sectors such as dairy, bottled water, sauces, and pharmaceuticals where microbial control is essential.

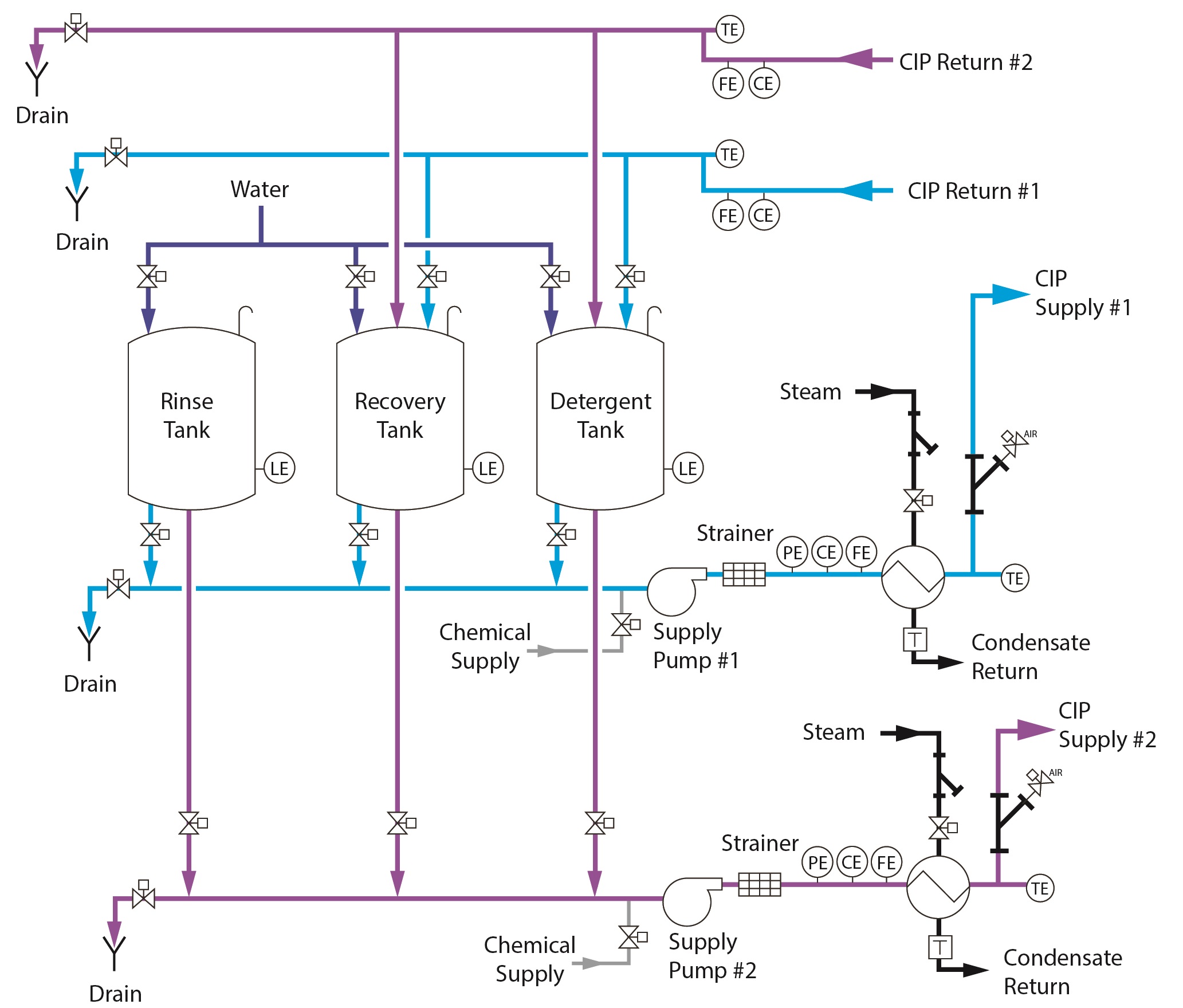

Traditional cleaning methods often require operators to stop the machine, dismantle parts, clean them manually, and reassemble. With CIP:

Cleaning is automated – No need for extended shutdowns.

Shorter turnaround times – Increases daily production capacity.

Minimized labor effort – Operators can focus on monitoring and quality control instead of manual cleaning.

Manual cleaning can lead to inconsistent results depending on the operator’s skill and attention to detail. CIP systems, however:

Deliver uniform cleaning performance across all production cycles.

Use programmed parameters such as water temperature, chemical concentration, and cleaning duration for optimal results.

Reduce human error and ensure high repeatability.

While CIP liquid filling machines may require a higher initial investment, they can save significant costs in the long run:

Lower labor costs due to automation.

Reduced water and chemical usage thanks to precise dosing.

Extended equipment lifespan due to regular and thorough cleaning.

Manual cleaning can expose workers to hot water, cleaning chemicals, and sharp machine components. CIP eliminates much of this risk:

Cleaning takes place inside enclosed systems.

Minimal operator contact with hazardous substances.

Reduced workplace accidents and improved compliance with safety regulations.

Sustainability is increasingly important to manufacturers and consumers alike. CIP technology supports green manufacturing by:

Optimizing chemical use to avoid waste.

Recycling rinse water when possible.

Reducing energy consumption with efficient cleaning cycles.

CIP systems make it easier to switch between different products without cross-contamination:

Quick changeovers between batches.

Safe for both low-viscosity liquids (water, juice) and high-viscosity products (sauces, creams).

Ideal for facilities handling multiple product lines.

A CIP liquid filling machine offers much more than convenience—it delivers hygiene, efficiency, consistency, cost savings, safety, and sustainability. For manufacturers in competitive markets, investing in CIP technology is not just about meeting regulatory standards—it’s about gaining a long-term operational advantage.

By reducing downtime, improving safety, and ensuring consistent cleaning results, CIP liquid filling machines are a smart choice for companies that prioritize both productivity and quality.

Keywords for SEO: CIP liquid filling machine, benefits of CIP system, Clean-in-Place filling equipment, hygienic filling machine, automated cleaning for liquid fillers, CIP technology in manufacturing.